INSPECH in practice.

On this page we present three use cases that illustrate how INSPECH eliminated common challenges in road inspection.

Measuring the lifespan of taxiways and platforms at airports

The situation

A well-known Dutch airport wanted to know the Pavement Condition Index (PCI) and the residual constructional lifespan of a number of taxiways and platforms. The PCI is an example of a technical approach, which requires a manual examination of the pavement. The index was originally developed by the US Army Corps of Engineers, but was later standardized by the ASTM. The surveying processes and calculation methods are documented and standardized by ASTM for airport roads and sidewalks. Commissioned by NACO Airport Consultancy & Engineering, Unihorn has carried out investigations of the pavement and drafted recommendations. What was special about this project was the way in which the input for the PCI determination was collected. Normally this is done manually but thanks to INSPECH this aspect of the PCI process was automated.

The solution

The current state of the asphalt and concrete pavements were recorded with HD video cameras and defect locations determined by GPS using a specially equipped Unihorn vehicle driven along the taxiways. Subsequently, the observable defects from the video images were identified by INSPECH in accordance with the criteria of the ASTM D5340-20 standard.

To determine the PCI values, Unihorn then built a database in MicroPaver with a section and sample unit layout. After entering the defects, the PCI values were calculated with MicroPaver.

The answer

Thanks to INSPECH, the condition of the airport pavement infrastructure has been mapped out completely, quickly and in detail for both the client and the airport. In addition, INSPECH allows automatic comparisons between multiple inspections, enabling trend analysis and PCI forecasting per sample unit. By comparing the PCI inspection results of previous inspections with the most recent results, a prognosis for the development of the PCI value for the next 5 years has been established.

Improving the overall maintenance of A-lanes A15

The situation

A-Lanes A15, a partnership between Ballast-Nedam, John Laing and Strukton, has been commissioned by Rijkswaterstaat (Dutch Department of Waterways and Public Works) to widen the A15 between Maasvlakte and Vaanplein within a Design, Build, Finance & Maintain DBFM agreement. The area includes 37 km of highway, the Botlektunnel, the Thomassentunnel and the Botlekbrug.

Every year, A-lanes A15 must demonstrate the contract requirements are met and has to draft an asphalt repair plan annually. Visual inspection is therefore crucial and damages must be recorded according to the visual inspection system of Rijkswaterstaat (the DWW method).

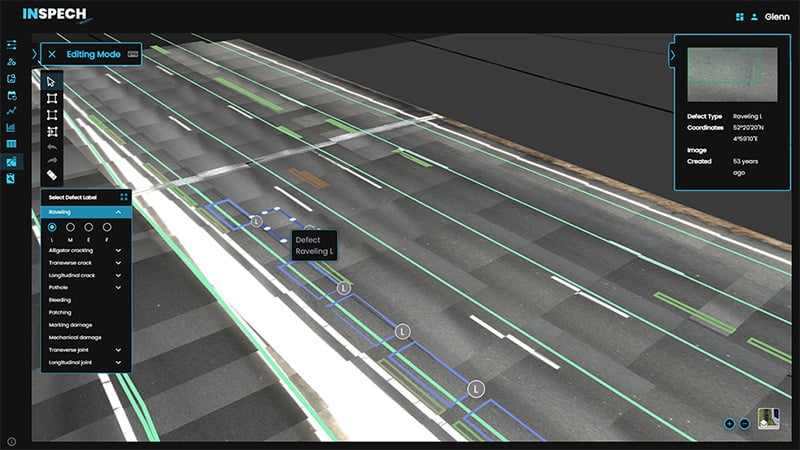

The solution

For this project it was important to be able to inspect OPA8 asphalt concrete. This is a fine and open asphalt concrete with a high percentage of hollow space (25%). As a result, the mixture deviates considerably from the regular open top layers, which meant that INSPECH had to undergo additional training. This was achieved in just a few days which enabled INSPECH to very quickly inspect the A15 as required.

The answer

Thanks to INSPECH, A-Lanes now have a reliable way to assess the condition of the asphalt road surfaces. In previous inspections, carried out by human inspectors, too many inconsistencies in assessment had arisen between different inspectors. Also over the years, the variations in inspection results mean that creating and managing maintenance plans proved difficult.

INSPECH assesses road condition in a consistent and repeatable manner, making it easier to draft maintenance plans and predict rates of deterioration of the infrastructure assets.

In order to meet the contractual requirements, it was important for the client to carry out the inspection as late as possible in the year and for an asset manager to have access to the results at any time in order to plan maintenance. Thanks to INSPECH, better maintenance planning is possible, which benefits both parties. The combination of collecting HD video images and inspecting the road surface with INSPECH cut the project lead time by more than half. This complies with the desired ‘postponement’ of the inspection to later in the year.

Transport for New South Wales, Australia

Background

AECOM has been working on the 'Hawkesbury-Nepean Valley Flood Evacuation Road Resilience Program' since 2023, to assist TfNSW in improving the flood resilience of the Valley by improving the flood evacuation routes.

Challenge

Two components of the Program entailed expanding the current road to create an evacuation shoulder spanning over 30 km. Similar to any widening project, a pivotal element for the pavement design was comprehending the pavement condition to propose a suitable assessment for connecting the existing and new pavement. A detailed study from the desk revealed significant variability in both the pavement composition and condition. Consequently, there was a need for a precise and robust method to map out the pavement condition. Conventional walkover site visits were ruled out due to safety concerns and cost implications.

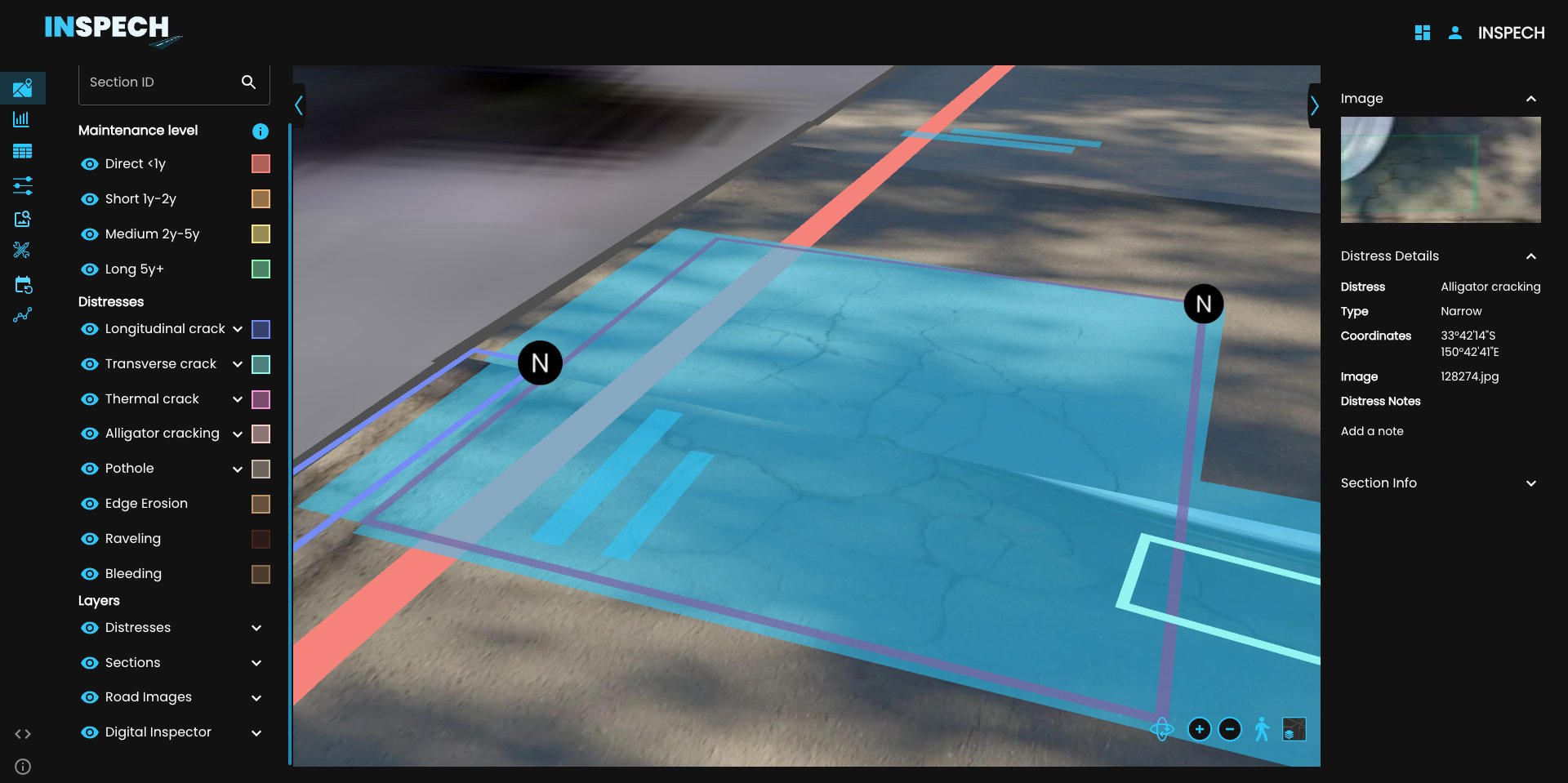

Solution

AECOM collaborated with INSPECH to introduce a digital road inspection solution, enhancing the efficiency of pavement condition assessments. This involves a visual inspection method using a GoPro camera mounted at the rear of a vehicle, capturing high-resolution images of the road surface from a downward perspective. These images are then integrated onto digital maps, producing an interactive, geo-referenced digital twin. This innovative approach streamlines the inspection process for human inspectors by providing augmented Assisted Visual Inspection (AVI) recommendations. This allows inspectors to validate and make adjustments swiftly, efficiently, and with greater reliability. The outcome provided mapping of all distresses in the 30 km extension of the road. The information helped reduce the subsequent pavement design effort and the subjectivity when liaising with stakeholders about the condition of the pavement.

Key Benefits

- Speed of carrying out the survey compared to other methods.

- Safety as it does not require assessment out of the car.

- Capability for detailed assessment on long corridors by using AI to map and categorise distresses.

- Reduced on-site time and office work by min. 4 weeks and reduced costs by no less than $20,000 (AUD).

- The web platform, and the ability to download outputs, eased the process of sharing information and collaboration with the design team, Clients and stakeholders through a “no charge” Digital Report Viewer.

- Ability to pinpoint focus areas and quantify rehabilitation needs with ease.

Lessons learned

- The GoPro camera rig configuration is key to achieve an effective recording. Some trials were needed to determine the best configuration.

- Once the rig is stable, a continuous recording is preferable, as it removes the office work and potential use of incorrect recordings encountered when frequent stop/starts are made.

- Continuity in staff is recommended once the rig settings are determined.

Created with road professionals, for road professionals.

Experience the future of road inspection.